|

| Puzzle Box |

A goal without a plan is just a wish.

― Antoine de Saint-Exupéry

Virtual Boatbuilding

To build for real, it helps to build in your mind, first.

Working out the order of construction in your head(s) influences your choices of materials, tools and infrastructure (sheds, jigs, power supply, etc.). It streamlines and coordinates effort, promoting efficiency. It keeps the horse ahead of the cart.

Believe me, we need all the help we can get!

Here's a general order for upright construction:

- Set up the Worksite - Shed, workbench, building jig.

- Build (and assemble) the Deadflat - This makes a large, flat work surface.

- Build and frame the Bulkheads - We'd best know ahead-of-time how furniture will fit, down-the-road!

- Build and frame the Sides - Let's say, full length.

- Erect Bulkheads and Sides - Got an order pictured? A method??

- Complete the Bottom Ends - Vague, very vague... a solid plan required here.

- Build Furnishings, Room by Room - Line 'em up, knock 'em down.

- Deck the Hull - With blows and pucky, falalalalaaaa, fala, la, la.

- Build Superstructures - Trunk Cabins, Hatches, Tabernacles, etc..

- Finish - Putty 'n paint, to make 'er what she ain't.

- Detail Work - Handrails, Coamings, CapRails, Hardware.

- Launch - What's your exit strategy?

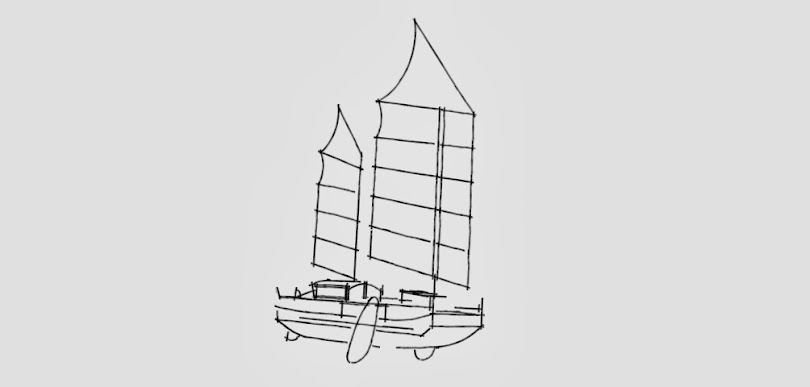

- Rig Aloft and Alow - Masts, Sails, Hardware aloft; Stove, Cushions, Bedding, etc., alow.

- Liquidate your Land Assets - Worksite, and whatever else you can part with.

- Sail over the Horizon - Bet we had this part in our heads from day one!

Straightforward, in many ways. The first six are those requiring the most thought. They're the big, heavy puzzle pieces that must all be made to fit together. After that, it's pretty much a down wind reach.

If short-handed, the Bottom and Sides can be built in a modular manner... this means in small, interlocking parts that can be positioned and assembled in manageable bits.

Finish can be a floating step, working as we go.

One of our mentors would end each work day with an hour of painting. He'd mark off where he was going to be gluing one piece to the next with a heavy hand, pressing an indent line into the plywood surface. Then he'd paint outside these lines and a little bit over the line. Next day - paint dry - he'd assemble and glue, using the indents to position his work.

By not deferring finish issues to the end, he was able to launch as soon as carpentry was complete. Taken in one go, Finish is a sizable and somewhat daunting task.

We've manage only a bit of this... it takes true organization, and a daily dedication to shop cleanliness that we have yet to achieve. But it's an option.

*****

A clear picture in our mind(s), and at least one, workable solution in hand for each problem is strongly recommended before our first cut.

We can wing it, here and there, especially if there's no shortage of materials available, or if we have general experience with some particular aspect. But there's a danger in this... amazing how often some unlooked-for conflict will blindside us if we haven't pictured every detail.

Visualization aids - paper and pencil, mainly - are handy. I personally like a roll of butcher paper, and a block of quarter inch graph paper. There are a lot of balls to juggle, in boatbuilding. Cheat! Consider keeping a notebook of the latest and greatest solutions. What's fresh in the moment of victory may slip away in the next round.

One thing I find... when the elegant solution comes, you know it's right. If an approach feels awkward, keep at it... think out of the box... something will occur to you.

So this is what's been keeping me up nights. Ordering and reordering in my head. Copper Plate doesn't exactly simplify things.

But it's a winning battle!

Most of my boatbuilding preps take place in my head. I can spend what seems like ages puzzling it out before I actually make or do anything. I have little on paper, most of it is more like what I imagine things should look like. My back of the envelope drawings don't necessarily end up exactly like I imagined it, and the actual result (the boat) does not always end up exactly as the drawings or the ideas! I am lucky in that I have very good spacial awareness, I can visualise the results I want to achieve quite clearly . does not work for everybody, but works for me. Not so good with the words to describe it though.

ReplyDeleteHi Joel,

DeleteWhat a gift! My spatial visualization is good, so long as I've got a paper crutch. Even then, some things stump me.

For instance, I took the time to render those flush hatches in SketchUp, which allows me to orbit the view... my materials counts for it finally agreed! I would've eventually got it with paper, I suppose, but not without real struggle.

Dave

There's that one chair in the shop that gets a lot of use for these times for me..... my wife calls it "The Chair of Woe". A good set of plans lessens butt time in said chair radically. Or a simple design like a trilo. I have grown to enjoy my woe time somewhat though and later in the day it often turns into the chair of woe AND microbrew destroying. One of my favorite boatbuilding seat of the pants periods.

ReplyDeleteHi BonRobi,

Delete"Chair of Woe"... I like it! Beats the "Moaning Chair".

And you're right... there's a certain, perverse pleasure to mulling over these puzzles. And a beer - in moderation, of course, mindful of the appetites of power-tools - certainly lubricates the gears!

Dave Z

Dave,

ReplyDeleteThe one absolutely essential help I got from a handful of friends that I could not have continued the boat without was the lifting of one-piece sides onto the bulkhead-framed dead-flat center. For a mere 24' barge hull those sides were heavy. How do you plan to proceed on your much longer boat? Will there be a set of lifting hands there at the time?

Wes

Hi Peter,

DeleteThere's a chance of more hands, but I doubt we'll be able to count on them (more on our remote building location, later).

So we're going to build by divide-and-conquer. Some of the framing is longitudinal - counter and platforms, chine and sheer nailers. These will be let into notched bulkheads to provide a jig. Then the sides will be joined and butted in place, sheet by sheet. Doubling plates last. Each piece is small enough to be manageable.

At least we think. A set of A-frame legs with a come-along can be used to crane the sides into position. This has some definite advantages, and we haven't ruled it out. It will partly depend on where our shop is located, exactly, and whether sufficient anchor points can be worked out. Headroom of the shop is another potential issue. We won't likely make a truly final decision until the last minute.

If one were building on crossbeams of sufficient breadth (instead of the longitudinal jig), the sides could be preassembled and then merely stood up (not lifted), which is a much simpler operation. But they take a lot more material and shop space.

WoodBoatMagazine had an interesting article on single-handed boat-building, emphasizing the heavy lifting, and Jan Adkin's book "Moving Heavy Things" is inspirational. Also, great scenes in Jack London's "The SeaWolf" about restepping a large schooner's masts, short-handed.

Dave Z

That’s right. In a big project like this, you really need a lot of time to organize and plan all the tasks, for you to determine which ones to do first and need more of your attention. And it’s wise to write it all down. At least you won’t forget about it, or could check back on what has already been done. And I think it will be better as well to write down all the materials you need and its specifications. So when you start to canvass for prices, it will be easier less stressful somehow.

ReplyDeleteKelley Burton @ Aim Dynamics